Choose your country / language

- EN Language

- Pulp, Paper & Printing

Yankee Dryers

The Yankee dryer is the heart of a tissue machine. It needs to retain a stable surface for creping, withstand high loads of creping and cleaning blades, and cope with occasional dry running situations. Optimized thermal sprayed coatings, often referred to as Yankee metallization, are compatible with the organic Yankee coating and resistant to chatter. These coatings provide creping stability with ceramic-tipped blades and allow trouble free operation that is demanded by tissue producers. State-of-the-art electric arc wire spray equipment allows our customers to operate with reliability and achieve top-notch results for time-critical, on-site coating projects.

No Chatter is What Matters

High-quality thermal spray coatings on a Yankee dryer protects the tissue mill’s assets by prolonging the cast iron Yankee life significantly. A coating lifetime of over 10 years in operation is achievable, while a Yankee without a coating would need a regrind every couple of years. A thermal spray coating can also be reapplied, when required, with almost no loss of material thickness on the Yankee shell. This makes thermal spray a perfect solution for steel Yankees as well.

Oerlikon Metco’s spray equipment and a full range of materials for consistent on-site spraying is the ideal solution for high-performance Yankee dryer coatings. Our proven SmartArc™ arc spray technology provides the quality, stability and consistency needed for coatings in these challenging on-site environments.

With the Oerlikon Metco solutions, you can achieve

- Highly wear-resistant coatings that are compatible with the organic chemistry

- High application rates and good application economics

- Economical coating solutions with reliable, high-throughput spray technology

- Cleaner on-site operation with new low-dust materials with excellent cohesive and adhesive strength

- Excellent reproducibility and consistent microstructure for optimal Yankee performance, long life and low chatter

Oerlikon Metco delivers materials ranging from economical standard feedstock wire products to high-end materials engineered using our proprietary Scoperta™ rapid alloy development methodology. The wires are designed to work reliably and repeatably with Oerlikon Metco’s electric arc wire spray equipment.

Our extensive process, material, and application knowledge allows us to find the optimum solution for our customers’ needs — through standard materials and processes or unique solutions developed using our Coating Solution Centers and/or through joint R&D collaboration.

- Environment

- Wiki-Tissue

- Nalco Water

Steel Yankee dryer: Advantages, development and rapid acceptance

This section will mainly cover the Steel Yankee Dryer , which has been rapidly adopted by the industry over the past 15 years. This text also briefly covers some basic principles of sheet drying on a tissue machine. However, these principles will be covered in much more detail in a separate section entitled Drying: Yankee dryer & Air hood .

Basic principles of the Yankee After pressing, on a conventional wet press machine, the tissue sheet is approximately 40-45% solids and the remaining water must be removed by using thermal energy to evaporate it. This is most often accomplished on a single large metal cylinder, the Yankee dryer, which can be up to 22 feet (6.7 m) in diameter and serves to both carry the sheet as well as drying it until it has reached the dryness and strength required to get the final paper quality.

The Yankee is partially enclosed by a high-velocity impingement hood and, in modern conventional tissue machines, at least 50 to 60 % of drying effect typically comes from the cylinder side, while 40 to 50% comes from the hood side.

The heart of the machine For several reasons, the Yankee dryer is often considered the heart of a tissue machine . This is due not only to the size of the cylinder, which can be enormous, but also the critical role it plays for:

• Supplying the energy needed for drying the wet web • Transporting and supporting the sheet during the drying process • Functioning as a roll in the hot-pressing operation • Providing the base for the creping process , in conjunction with the doctor blade.

By the way, the origin of the name “Yankee” for this drying cylinder is a bit of a mystery. There are several theories about where it comes from but no definitive reason for this name has been firmly established, as far as we know.

Cast-iron was the standard for a century For almost 200 years cast iron has been the material used for Yankee cylinders. Over the years, advances have been made in cast iron Yankees, such as improving material properties, strength, and heat conductivity, as well as enhancing the design by changing from a smooth inside shell to one with grooves and ribs.

Starting around 2000, Steel Yankee Dryers began to be introduced as a Tissue drying concept. Improvements in manufacturing methods, and especially in welding technology, made steel Yankee cylinders feasible. This offered new opportunities to papermakers which will be covered below.

Toscotec pioneered steel Yankee dryer, based on 40 years’ experience Toscotec, the paper machine producer in Lucca, Italy, is widely seen as the pioneer and driving force for development of the steel Yankee dryer (SYD) concept. Already in the 1960s, the company was producing steel drying cylinders for standard paper machines. In 1999, Toscotec started to design the first SYD based on emerging methods of engineering analysis and in 2000 the first steel Yankee, 2.5 m (8 feet) in diameter, was officially started in commercial operation on a tissue machine.

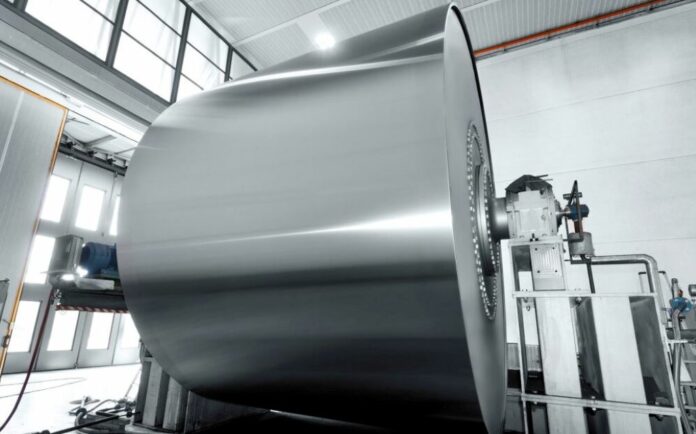

In 2013 the company launched its second-generation design, with a diameter of 22 feet, a width of 5.6 m and an operating speed of 2000 m/min. This is the largest diameter steel Yankee ever made so far and, it is claimed, the fastest ever using steam only as the heating source in the drying process.

Steel has many advantages Steel offers the tissue maker numerous advantages in terms of safety, energy consumption, flexibility, investment costs, and weight.

Safety is of course a very important consideration for companies. Explosions on cast iron Yankee dryers unfortunately have sometimes occurred due to the material properties of cast iron. Thus the cylinder can explode if it is over pressurized, loaded with excessive load, or in case of an accident for other reasons. Steel, on the other hand, will have a better performance in the event that internal stresses exceed the allowable limits.

Since steel is a stronger material and has a modulus of elasticity which is considerably higher than cast iron, the pressure vessel safety codes allow for better design parameters on steel. The much higher allowable stresses for steel mean that the shell wall can be thinner , which gives the positive benefit of higher heat transfer . The shell root thickness on a SYD can be approximately 30% lower than a cast-iron shell.

Lower shell root thickness for steel means the resulting heat flow is higher through the cylinder. This gives a higher evaporation rate which can flexibly either be used: to increase the production rate at constant energy input or, when the machine speed is kept constant, to reduce the drying energy.

Higher heat transfer and lower energy costs Cast iron and steel have essentially comparable thermal conductivities, so if the shell is 30% thinner, heat transfer increases accordingly with steel, giving greater drying efficiency. Since drying is accomplished by a combination of the Yankee and the hood, the increased heat exchange efficiency translates to over 15% increase in production capacity at constant energy input.

Another benefit of the reduced shell thickness and higher heat transfer is that lower steam pressure can be used for drying. In such a case, the same production rate can be reached using lower steam pressure.

Alternatively, the tissue machine can utilize more steam, and less hood contribution and electricity , to produce the same amount of paper. The result is lower total energy consumption. Depending on the cost ratio between the different energy sources, energy cost savings of up to 20% are possible in tissue machines with a SYD. The investment cost for steel Yankees are normally somewhat lower than for the cast iron variety, and the physical weight is 25 to 30% less as well.

Metalizing benefits It should be mentioned that steel Yankee dryers are metalized prior to delivery because the steel itself is too soft for creping and the wear rates would be unacceptable. Metallization eliminates the need for re-grinding of the shell wall base metal, which on cast iron can eventually result in de-rating. Metallization is also a key reason that steel Yankees are far less prone to developing chatter problems.

Summary In summary, steel Yankees have major advantages compared with cast iron in safety matters, and also in energy costs due to higher drying capability in the Yankee-to-Hood drying balance. Steel Yankees therefore offer potential energy cost savings, while also having a lower capital investment cost than cast iron. Although the SYD technology was pioneered by Toscotec, essentially all the major tissue machine suppliers have begun making steel Yankee dryers and offer them to the market today.

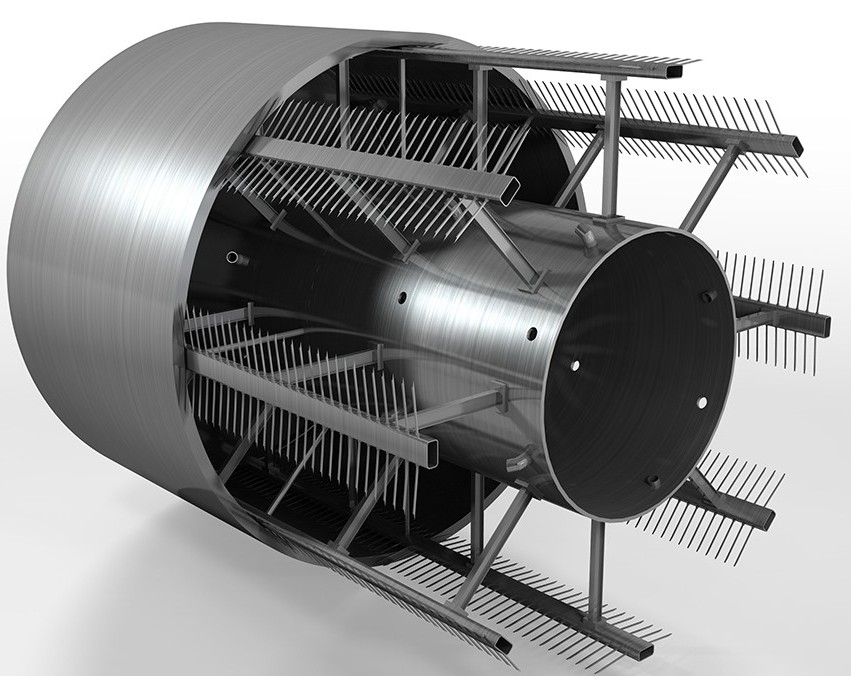

Internal view, Toscotec SYD

Comments are closed.

Recent Posts

- PrimeLineTEX tissue machine and quality exceeds expectations

- Sofidel continues to ‘walk the talk’ with CO 2 reducing initiatives

- 100% Carbon-Fiber expanding shaft allows both faster max speeds and acceleration/deceleration

- The Basics of Creping in the Tissuemaking Process

- Technologies to reduce carbon emissions in tissue production

- I Am in Spec . . . but Where Did my Softness Go?

- IKEA disconnects air dryers, citing risk of spreading Covid. Paper towels used instead. Bravo!

- September 2023

- January 2021

- September 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- January 2019

- December 2018

- September 2018

- February 2018

- November 2017

- September 2017

- August 2017

- February 2017

- October 2016

- E-NEWS SIGN-UP

Magazine menu

- Mills & Technologies

- Sciences & Innovations

Toscotec to supply a TT SYD Steel Yankee Dryer to Mirae Paper

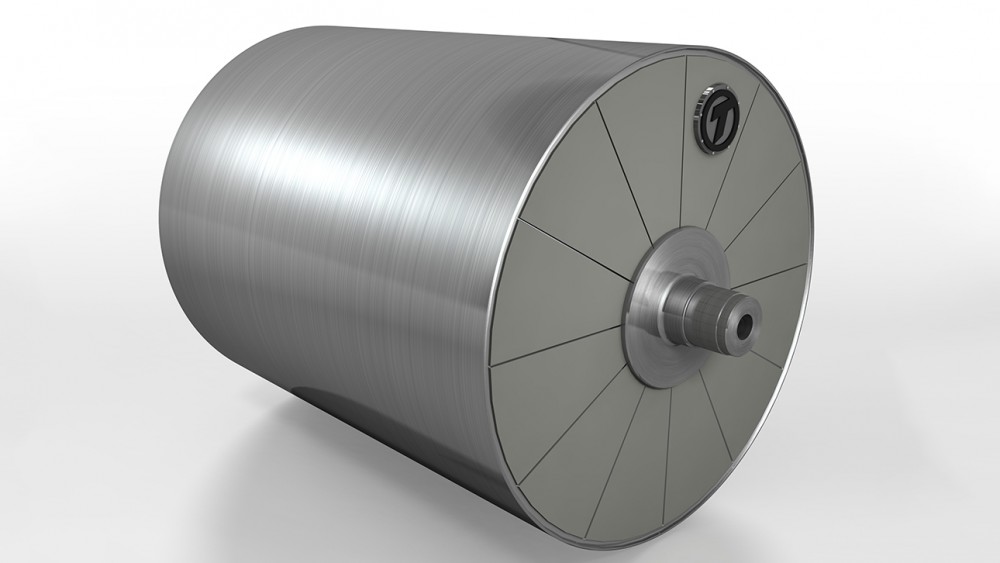

Toscotec’s TT SYD Steel Yankee Dryer

- Previous Article DS Smith partners with Trimble to drive digitalisation at its paper mills

- Next Article Sun Paper relies on Pasaban for the supply of eighteen new paper and board sheeters in China

- Smaller Small Medium Big Bigger

- Default Helvetica Segoe Georgia Times

- Reading Mode

Toscotec will supply a third-generation design TT SYD Steel Yankee Dryer to the South Korean tissue manufacturer Mirae Paper at their Jeonju paper mill. This is a repeat order from Mirae Paper who installed their first TT SYD on PM3 in 2013.

The new steel Yankee will replace PM2’s existing cast-iron cylinder and it is scheduled for start-up in the second half of 2022.

The third-generation design of TT SYD Steel Yankee Dryer benefits from an ideal ratio of the weight, width and pitch of the internal ribs and the optimization of the shell thickness. The scope of supply includes the condensate removal system and Toscotec’s patented heads insulation for maximum thermal energy efficiency . The associated services include the complete project management, erection supervision, operation and maintenance training, commissioning and start-up assistance.

The TT SYD will be manufactured at Toscotec’s fully integrated TT SYD Technology Center in Massa (Italy), situated just 3 kilometers away from seaport to ensure fast and safe shipping operations.

Toscotec is continuously upgrading the design of TT SYD, benefiting from the vast experience of over 200 TT SYD running across 5 continents worldwide under the most diverse operational and environmental conditions. This year, Toscotec has launched TT Defender ® , a breakthrough patented innovation that equips TT SYD with an internal protection coating against corrosive steam.

Yeong Rok Lee, Mirae Paper’s Production Manager , says, “The steel Yankee on PM3 has been operating efficiently for over 8 years, allowing us to reduce our thermal energy consumption by a significant amount. We expect the new Yankee on PM2 to be as reliable and to deliver even higher performances, considered the design upgrades that Toscotec has implemented on their TT SYD since our first installation. We consider the Yankee dryer to be the core component of our tissue machine’s drying capacity. We chose the best technology available in the market, with all the technical support we need from an expert supplier.”

Gabriele Martinelli, Toscotec’s Sales Manager , says, “It is very rewarding that Mirae Paper has chosen Toscotec for the second time on their Yankee replacement. Toscotec strengthens its position in South Korea, where it is the only supplier of steel Yankee dryers, with 12 TT SYD sold in 9 years, including two installed on Toscotec’s AHEAD tissue lines.”

This order was obtained with the support of CleanTech Corporation, Yongin, South Korea.

About Mirae Paper Co., Ltd. Established in 2000, Mirae Paper operates one paper mill in Jeonju, South Korea. The company manufactures approximately 65,000 tpy of high quality tissue, including toilet tissue, handkerchiefs, and towels, using recycled fibers. It distributes its products mainly to the Korean market.

Source: Toscotec

Related Articles

- Toscotec to supply Turkey’s biggest tissue machine to Essel Kağıt on a turnkey basis

- Toscotec completes a major rebuild of Arapepco’s PM1 in Aleppo, Syria.

- Toscotec to rebuild the dryer section of PM4 at Aviretta, Germany

- Toscotec receives forth turnkey order from WEPA

- Toscotec launches new OPTIMA rewinders for top winding quality and efficiency

Tissue World Magazine is part of the Informa Markets Division of Informa PLC

- Informa PLC

- Investor relations

Tissue World Magazine is operated by a business or businesses owned by Informa PLC and all copyright resides with them. Informa PLC's registered office is 5 Howick Place, London SW1P 1WG. Registered in England and Wales. Number 8860726.

- Northern America

- Southern America

- Consumer Speak

- Frontissues

- Marketissues

- Operations Report

- Egypt & Jordan

- Latin America

- Middle East

- North America

- Northeast Usa

- Scandinavia

- South Africa

- South Korea

- Environment

- Paper Machine

- Pulping / Fibre

- Annual Review

- Distribution Special

- Geopolitics

- Private Label & Brands

- Project Survey

- Retail Special Report

- The Barometer Issue

- PRINT SUBSCRIPTION

- DIGITAL SUBSCRIPTION

- EDITORIAL CALENDAR

- EVENTS CALENDAR

Navigator Paper UK makes offer to acquire Accrol Group

K-c unveils restructuring initiatives focused on growing brands and businesses.

Northwood Tissue boosts capacity with PrimeDry Hood investment

Hengan launches TAD products into the Chinese tissue market

EXITISSUES: Inflation appears to be reducing in most developed nations –…

CONSUMERSPEAK: It’s in the bag – from the most colourful shop…

MARKETISSUES: Profitable growth in the consumer tissue value chain – where…

ESSITY OPERATIONS REPORT: Supply chain integration the key as diverse Latin…

LATIN AMERICA REGIONAL REPORT: Economic headwinds impact tissue consumption growth

LATIN AMERICA REGIONAL REPORT: Consumers want sustainability – but the cost-of-living…

COUNTRY REPORT: Global pulp leader Brazil shows strong growth in finished…

COUNTRY REPORT: Brazil’s longer term tissue recovery ‘promising,’ but uncertainty remains…

The global trend demanding higher quality tissue products is rising

ENVIRONMENT TECHNICAL THEME: Turning 60% of all France’s recycled food and…

CONVERTING TECHNICAL THEME: “These times are definitely exciting” – with key…

Canfor embedding long-term sustainability across its day-to-day business

PROJECTS SURVEY 2024: Special Feature

GEOPOLITICS REPORT: 2024 is a year of election campaigning – it…

SPECIAL REPORT: Unveiling the future – the hygiene tissue industry in…

SPECIAL FEATURE: ANNUAL REVIEW 2023

Mirae paper boosts high-quality capacity with steel yankee.

South Korea’s Mirae Paper has invested in a Toscotec-supplied TT SYD Steel Yankee Dryer to be delivered to its Jeonju paper mill.

It will replace PM2’s existing cast-iron cylinder and is scheduled for start-up in the second half of 2022.

Yeong Rok Lee, Mirae Paper’s Production Manager, said: “The Steel Yankee on PM3 has been operating efficiently for over eight years, allowing us to reduce our thermal energy consumption by a significant amount.

“We expect the new Yankee on PM2 to be as reliable and to deliver even higher performances.

“We consider the Yankee dryer to be the core component of our tissue machine’s drying capacity.”

Toscotec said the third-generation design “benefits from an ideal ratio of the weight, width and pitch of the internal ribs and the optimisation of the shell thickness”.

The scope of supply includes the condensate removal system and Toscotec’s patented heads insulation for maximum thermal energy efficiency.

Established in 2000, Mirae Paper operates one paper mill in Jeonju, South Korea.

It manufactures 65,000tpy of high-quality tissue including toilet tissue, handkerchiefs, and towels, using recycled fibres, which are distributed primarily in the Korean market.

RELATED ARTICLES MORE FROM AUTHOR

Grigeo acquires GZP’s Niedomice tissue mill

Suzano announces April price hikes

Metsä launches consultation for planned UK tissue paper mill

Tissue World Miami 2024: The global tissue industry steps out in style

Clearwater reports net income up $61.7m in 2023; boosts paperboard presence with Augusta acquisition

Crown Paper boosts capacity by 70,000tpy with TM investment

Kruger Products reports “record sales” and investment in latest results

PT Sun Paper Source increases capacity with four TMs

PCMC launches tissue rewinder Paragon

Copyright © 2024. All rights reserved. Informa Markets, a trading division of Informa PLC.

- Accessibility

- Privacy Policy

- Terms of use

- Visitor Terms and Conditions Link

Latest News

Toscotec launches breakthrough in steel yankee dryers for sustainable papermaking.

Toscotec, the global market leader of Steel Yankee Dryers, introduces TT Induction SYD , a carbon-reduction breakthrough that redefines Yankee dryer technology entirely. TT Induction SYD uses electrical induction instead of steam energy to dry the paper web, thereby cutting direct greenhouse gas emissions to zero .

In 2000, Toscotec pioneered a major technological innovation, TT SYD , the first Yankee dryer entirely made of steel. Steel Yankees have since surpassed their cast-iron equivalent to become the benchmark for drying efficiency and safety in the paper industry. TT Induction SYD is now set to be the new game changer in tissue for its capability to use clean energy and slash direct carbon emissions associated with the drying process.

A disruptive innovation for dry crepe and TAD tissue machines With TT Induction SYD, the internal steam distribution and steam/condensate removal systems are entirely replaced by an induction system composed of static coils installed inside the shell and electrical controls and instrumentation located outside for easy maintenance and monitoring. As a result of precise coil geometry, the induction system delivers a very fast and accurate heating effect exactly on the areas of the shell where it is required, while preventing residual circulating currents in other areas. Steam-heated Yankees use steam energy typically generated by burning fossil fuels. TT Induction SYD uses electrical energy that can be derived from renewable energy sources while delivering the same result, i.e. uniformly heating up the Yankee’s shell in contact with the paper web to achieve dryness. TT Induction SYD is suitable for installation on dry crepe as well as Through-Air-Drying (TAD) tissue lines.

Luca Ghelli, Toscotec R&D Director , says, “Sustainability is the guiding idea of TT Induction SYD’s design. As a proven industrial technology, an induction system offers multiple advantages when applied to the most energy-intensive section of the tissue machine. The efficiency of this cutting-edge technology will dramatically reduce the carbon footprint of papermaking. Based on our expertise in steam-heated TT SYD and induction systems, we succeeded in developing a more efficient and sustainable steel Yankee dryer.”

Substantial carbon reduction with unchanged productivity and paper quality Normally, approximately half of the carbon dioxide emissions produced by a tissue machine originate from the operation of the Yankee dryer. By using clean energy, TT Induction SYD achieves zero direct emissions, while maintaining productivity unchanged and reducing energy consumptions because of the higher efficiency of the induction system . Due to the precise heating of the shell, it also eliminates possible moisture profile issues related to uneven condensate removal, thereby ensuring an improvement in moisture uniformity in both cross direction (CD) and machine direction (MD).

Maximum safety, easier operation, and maintenance TT Induction SYD was designed without any electrical, mechanical, and radiation risk to ensure maximum safety. Besides offering safe operations , it also clears all issues related to the maintenance of steam-heated Yankees, including pressure vessel’s mandatory and planned controls, maintenance of condensate straw pipes against potential plugging and of special heads for steam and condensate inlet and outlet. The entire Yankee system is simplified in the absence of steam: the heads, the internal surface which is groove-less, and the steam and condensate auxiliary system disappears entirely, including the steam generator with related maintenance and controls and delicate controls for steam quality. TT Induction SYD simply requires relatively easy maintenance on the electromagnetic induction system.

- 'Share on Twitter'

Several Kemira manufacturing lines will close due to the ongoing political strikes in Finland

Metsä fibre starts negotiations on possible layoffs at kemi bioproduct mill, xuong giang paper has successfully started up its second tissue production line, emtec's innovative solutions for sustainable papermaking to be showcased at pulp & beyond 2024, vpk group further expands its presence in italy with iemme, kaicell’s paltamo mill venture receives court ratified environmental permit.

Finland’s Supreme Administrative Court has declined to hear the remaining appeals that were filed against...

West Fraser and Mercer announce dissolution of Cariboo Pulp and Paper JV

West Fraser Timber Co. Ltd. and Mercer International Inc. announced today an agreement to dissolve...

MES SUITE by T.CON: Paper and packaging production with more transparency, flexibility and sustainability

The release of “MES SUITE 7.0” by T.CON GmbH & Co. KG marks a fully...

Lithuania’s Grigeo completes Polish acquisition

Foreign acquisition Lithuanian cardboard maker Grigeo has finalised its takoever of a Polish paper mill...

Valmet’s change negotiations completed in Services and Paper business lines

Valmet announced on February 15, 2024, the start of change negotiations in certain parts of...

DS Smith completes acquisition of Serbian packaging company, Bosis doo

DS Smith announces the successful completion of our acquisition of Bosis doo, a high-quality packaging...

SteamDry: Pioneering Sustainable Drying Solutions for the Paper Industry

A European Consortium Led by VTT Introduces Superheated Steam Technology to Revolutionize Paper Production In...

Brittisk energijätte satsar stort på finsk solenergi

Den brittiska energiinvesteraren Renewable Power Capital (RPC) planerar att utöka sin närvaro på den finska...

Sappi Europe announces a further price increase for coated and uncoated fine papers

According to Sappi, prices for Coated and Uncoated Fine papers were increased during January and...

Hengan launches structured tissue products after Toscotec’s TAD machine start-up

Following the start-up of a Toscotec’s TADVISION® tissue machine, Hengan International Group has launched on...

Nine Dragons Paper shares FY2024 interim results

New data published China’s Nine Dragons Paper has released the company’s unaudited consolidated interim results...

FSC US announces new leadership

Forest Stewardship Council United States (FSC US) announced the appointment of Sarah Billig as its...

International Paper confirms proposal to acquire DS Smith

International Paper confirms that it has made an all-equity proposal to acquire the entire issued...

Valmet to deliver a wide range of shutdown services to Ittihad Paper Mill in United Arab Emirates

Ittihad Paper Mill (IPM) in Abu Dhabi, United Arab Emirates, has again selected Valmet as...

Suzano signs an agreement with Lin-gang Special Area Administration

On March 20th, Suzano signed an agreement with Lin-gang Special Area Administration in Shanghai. Leveraging...

Ukrainian Kokhava paper mill distributes dividends to shareholders

New decision Ukraine’s Kokhava paper mill has decided that, of the company’s net profit of...

Long production shutdown at Metsä Group’s Kemi bioproduct mill due to gas explosion

A gas explosion occurred at Metsä Group's Kemi bioproduct mill in the evaporation plant during...

ABB upgrades Japanese paper mill

Investment underway Swedish-Swiss company ABB has announced it is upgrading a pulp and paper mill...

Cascades is celebrating its 60th anniversary

Cascades celebrated its 60th anniversary yesterday. Hundreds of Cascades employees kicked off the festivities this...

Sonoco to increase prices for URB in Europe

Sonoco announced it is implementing a €60 per ton, £50 for UK market, price increase...

Accsys has added Mery Bois as a new distributor in Belgium

For over 30 years, Mery Bois has been importing and supplying a wide range of...

Andritz to supply high-temperature Yankee hood and air system to Northwood Tissue, England

Andritz has received a turn-key order from Northwood Tissue Ltd. to supply a new PrimeDry...

Essity completes divestment of its shares in Vinda

The hygiene and health company Essity has today completed the divestment of its entire holding...

- Fler nyheter

De Iuliis C&A

Record in emergency interventions to secure water production in the power and paper industry.

The lack of climate adaptation, inadequate safety margins, and aging equipment are behind many of...

Job listings

Va ingenjörerna, emtec electronic gmbh, nipman paper technology, gein maskiner ab, maf pump aktiebolag, reka cables, umv coating systems ab, disab-tella ab, kingspan-logstor ab, advanced industries packaging, head engineering ab, ringdahl maskiner ab, holmen paper, most read right now.

RESPONSIBLE PUBLISHER BY LAW

John Hardwick

© Conventus Media House AB 2017

Box 6219 102 34 Stockholm [email protected]

(+46) (0) 8-506 244 00

An Investigation of a Dryer Can Failure in a Paper Mill

- Technical Article---Peer-Reviewed

- Published: 21 January 2015

- Volume 15 , pages 251–257, ( 2015 )

Cite this article

- M. Ananda Rao 1 &

- M. V. Pavan Kumar 2

202 Accesses

Explore all metrics

The failure of a rotary dryer in a paper manufacturing facility is reported and analyzed. The primary cause of failure is identified as a weakened structure and as a consequence, inlet pressure of the steam into the dryer reaching a critical limit. Post failure, the shell, and the two heads of the dryer were analyzed using characterization techniques such as stereomicroscopy and scanning electron microscopy with energy dispersive analysis. The threads of the shell were found completely chipped off. In the microchemical analysis, silicon in the form of quartz was found inside the shell at the threads. Silica in the form of quartz is theorized as having entered through the steam and becoming entrapped in the gaps of the threaded connections. Although wear between brittle shell and the connecting bolts can potentially develop torsion and lead to the chipping off of the crest regions of the threads over the time, the deposition of silica might have instigated and aggravated the same.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: a review

Muhammad Aamir, Majid Tolouei-Rad, … Ataollah Nosrati

Failure Analysis of Air Tube Inlets in a High-Speed Power Turbine

H. R. Lashgari

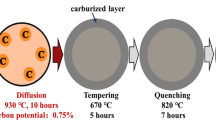

A study of the effect of dual shot peening on the surface integrity of carburized steel: combined experiments with dislocation density-based simulations

Jizhan Wu, Peitang Wei, … Huaiju Liu

A.K. Ghosh, Fundamentals of paper drying—theory and application from industrial perspective, in Evaporation, Condensation and Heat transfer , ed. by A. Ahsan (InTech Open Publishers, Croatia, 2011), pp. 535–582. ISBN 978-953-307-583-9

Google Scholar

R.T. King, Failures of Pressure Vessels, Failure Analysis and Prevention, ASM Handbook , vol. 11 (ASM International, Materials Park, 1986), pp. 643–669

J. Johnson, H. Thielsch, S. Freeman, Catastrophic failure of cast iron dryer roll caused by severe erosion resulting from spoiler bar failures, The TAPPI Engineering Conference, Dallas, Texas, 1995

M.H. Gilkey, Corrosion fatigue and subsequent rupture of a Yankee dryer roll on a modified paper machine, in Hand Book of Case Histories in Failure Analysis , vol 1, ASM International, 2002, pp. 132–135. ISBN: 0-87180-453-6

H. Thielsch, F. Cone, Failures and failure prevention of paper machine components, in TAPPI Engineering Conference , San Francisco, California, 1994

S.P. Fusco, Guidelines for the Safe Operation of Steam Heated Paper Machine Dryers (TAPPI, Atlanta, 1995). ISBN-13: 978-0898522952

R.O’Brien-Bills, N. Hoffman, R.H. DeWolf Sr., Development of Paper Machine Dryer Inspection Guidelines, www.TAPPI.org . Accessed 10 Nov 2013

S. Kitahara, The solubility equilibrium and the rate of solution of quartz in water at high temperatures and high pressures. Rev. Phys. Chem. Jpn. 30 , 123–130 (1960)

R.O. Fournier, The solubility of amorphous silica in water at high temperatures and high pressures. Am. Mineral. 62 , 1052–1056 (1977)

Download references

Acknowledgments

The authors thank the Director, the National Metallurgical Laboratories Jamshedpur for his encouragement in publishing this article.

Author information

Authors and affiliations.

CSIR-National Metallurgical Laboratory Madras Center, Taramani, Chennai, India

M. Ananda Rao

Department of Chemical Engineering, National Institute of Technology Calicut, Kozhikode, India

M. V. Pavan Kumar

You can also search for this author in PubMed Google Scholar

Corresponding author

Correspondence to M. Ananda Rao .

Rights and permissions

Reprints and permissions

About this article

Ananda Rao, M., Pavan Kumar, M.V. An Investigation of a Dryer Can Failure in a Paper Mill. J Fail. Anal. and Preven. 15 , 251–257 (2015). https://doi.org/10.1007/s11668-015-9922-y

Download citation

Received : 17 April 2014

Revised : 19 December 2014

Published : 21 January 2015

Issue Date : April 2015

DOI : https://doi.org/10.1007/s11668-015-9922-y

Share this article

Anyone you share the following link with will be able to read this content:

Sorry, a shareable link is not currently available for this article.

Provided by the Springer Nature SharedIt content-sharing initiative

- Corrosion weakening

- Catastrophic failure

- Failure analysis

- Metallurgical investigation

- Find a journal

- Publish with us

- Track your research

This site in other countries/regions:

Select country to see regional site for ametek land..

Industrial Processing

- Chemical Processing - Stack Emissions

- Forging - Drop

- Forging - Rotary

- Heat Treatment - Annealing

- Heat Treatment - Flame Hardening

- Heat Treatment - Induction

- Heat Treatment - Laser Hardening

- Heat Treatment - Plasma Nitriding

- Non-Wovens - Drying

- Non-Wovens - Hot Glue Laminating

- Paper - Stack Emissions

- Paper - Super Calendering

- Paper - Yankee Dryer

- Plastic - Extruding

- Plastic - Thermoforming

- Solar - Czochralski Process

- Solar - Photovoltaic Module Assembly

- Solar - Polysilicon Ingot Casting

- Solar - Polysilicon Reactors

- Specialist Coating - Plasma Ceramic Coatings

- Wood - Wood Chips on Conveyor

Yankee Dryer

Related products +.

LSP-HD Linescanner

Compact and sophisticated high accuracy infrared linescanner, designed to produce advanced thermal images of moving processes.

Keep Reading

FOLLOW US ON SOCIAL MEDIA

[email protected]

+44 (0)1254 830486, heavy machinery, design - build - install - maintain - upgrade - rebuild - relocate, paper making machinery.

YANKEE DRYER SERVICES

UMBILICAL LAYUP MACHINERY

OFFSHORE EQUIPMENT

GENERAL ENGINEERING

New York Times Statement About 1932 Pulitzer Prize Awarded to Walter Duranty

Duranty, one of the most famous correspondents of his day, won the prize for 13 articles written in 1931 analyzing the Soviet Union under Stalin. Times correspondents and others have since largely discredited his coverage.

Duranty’s cabled dispatches had to pass Soviet censorship, and Stalin’s propaganda machine was powerful and omnipresent. Duranty’s analyses relied on official sources as his primary source of information, accounting for the most significant flaw in his coverage – his consistent underestimation of Stalin’s brutality.

Describing the Communist plan to “liquidate” the five million kulaks, relatively well-off farmers opposed to the Soviet collectivization of agriculture, Duranty wrote in 1931, for example: “Must all of them and their families be physically abolished? Of course not – they must be ‘liquidated’ or melted in the hot fire of exile and labor into the proletarian mass.”

Taking Soviet propaganda at face value this way was completely misleading, as talking with ordinary Russians might have revealed even at the time. Duranty’s prize-winning articles quoted not a single one – only Stalin, who forced farmers all over the Soviet Union into collective farms and sent those who resisted to concentration camps. Collectivization was the main cause of a famine that killed millions of people in Ukraine, the Soviet breadbasket, in 1932 and 1933 – two years after Duranty won his prize.

Even then, Duranty dismissed more diligent writers’ reports that people were starving. “Conditions are bad, but there is no famine,” he wrote in a dispatch from Moscow in March of 1933 describing the “mess” of collectivization. “But – to put it brutally – you can’t make an omelet without breaking eggs.”

Some of Duranty’s editors criticized his reporting as tendentious, but The Times kept him as a correspondent until 1941. Since the 1980’s, the paper has been publicly acknowledging his failures. Ukrainian-American and other organizations have repeatedly called on the Pulitzer Prize Board to cancel Duranty’s prize and The Times to return it, mainly on the ground of his later failure to report the famine.

The Pulitzer board has twice declined to withdraw the award, most recently in November 2003, finding “no clear and convincing evidence of deliberate deception” in the 1931 reporting that won the prize, and The Times does not have the award in its possession.

We use cookies and similar technologies to recognize your repeat visits and preferences, as well as to measure and analyze traffic. To learn more about cookies, including how to disable them, view our Cookie Policy . By clicking “I Accept” on this banner, you consent to the use of cookies unless you disable them.

IMAGES

VIDEO

COMMENTS

Yankee dryer. A Yankee dryer is a pressure vessel used in the production of machine glazed (MG) and tissue paper. On the Yankee dryer, the paper goes from approximately 42-45% dryness to just over 89% dryness. In industry, MG cylinders or Yankee dryers are primarily used to remove excess moisture from pulp that is about to be converted into ...

The Yankee dryer is the heart of a tissue machine. It needs to retain a stable surface for creping, withstand high loads of creping and cleaning blades, and cope with occasional dry running situations. Optimized thermal sprayed coatings, often referred to as Yankee metallization, are compatible with the organic Yankee coating and resistant to chatter. These coatings provide creping stability ...

Compared with the replaced cast iron Yankee, it is delivering substantial energy savings, which reduce the overall operating costs of the tissue machine. Indisputable market leadership Toscotec holds a large majority of the global market share of Steel Yankee Dryers boasting more than 260 TT SYD sold worldwide.

Toscotec pioneered steel Yankee dryer, based on 40 years' experience Toscotec, the paper machine producer in Lucca, Italy, is widely seen as the pioneer and driving force for development of the steel Yankee dryer (SYD) concept. Already in the 1960s, the company was producing steel drying cylinders for standard paper machines.

Toscotec, the global market leader of Steel Yankee Dryers, introduces TT Induction SYD, a carbon-reduction breakthrough that redefines Yankee dryer technology entirely.. TT Induction SYD uses electrical induction instead of steam energy to dry the paper web, thereby cutting direct greenhouse gas emissions to zero.. In 2000, Toscotec pioneered a major technological innovation, TT SYD, the first ...

Yankee Dryer Overview. Module 1: Yankee Dryer Design and Construction. Module 2: Yankee Dryer Steam and Condensate Systems. Module 3: Yankee Dryer Coating. Module 4: Yankee Hoods and Air Systems. Module 5: Yankee Dryer Safety. Module 6: Yankee Dryer Dry Creping Basics.

Incorporating new materials such as microfibrillar cellulose in the stock could be a challenge for the existing paper dryer. For an integrated mill, the multicylinder dryer is mainly based on renewable energy from the recovery boiler but impingement and Yankee dryers sometimes use large amounts of natural gas or liquefied petroleum gas ...

Toscotec will supply a third-generation design TT SYD Steel Yankee Dryer to the South Korean tissue manufacturer Mirae Paper at their Jeonju paper mill. This is a repeat order from Mirae Paper who installed their first TT SYD on PM3 in 2013. The new steel Yankee will replace PM2's existing cast-iron cylinder and it is scheduled for start-up in the second half of 2022.

The Yankee Dryer Evolution • 1820 the paper drying cylinder was first patented. Normally heated by charcoal fire. • ~1850 the "Yankee paper making machine" Steam heated drying cylinders came into use. • ~1900 Yankee diameters 2-3 m, steam pressures 0-200 kPa. • ~1950 Yankee diameters 5 m. • 1959 the internally ribbed Yankee

July 13, 2021. South Korea's Mirae Paper will start up a Toscotec-supplied a TT SYD Steel Yankee Dryer at its Jeonju site. South Korea's Mirae Paper has invested in a Toscotec-supplied TT SYD Steel Yankee Dryer to be delivered to its Jeonju paper mill. It will replace PM2's existing cast-iron cylinder and is scheduled for start-up in the ...

The Yankee dryer is a specialized pressure vessel used in the production of tissue paper to remove excess moisture from pulp that is about to be converted to paper, said ST Paper mill manager Gary ...

Toscotec, the global market leader of Steel Yankee Dryers, introduces TT Induction SYD, a carbon-reduction breakthrough that redefines Yankee dryer technology entirely. TT Induction SYD uses electrical induction instead of steam energy to dry the paper web, thereby cutting direct greenhouse gas emissions to zero. In 2000, Toscotec pioneered a major technological innovation, TT SYD, the first ...

Paper plants use several methods to bring heat to the dryer drums. The most common are Steam Cylinders (Yankee Dryers), Air dryers and Infrared (IR) dryers. Infrared dryers are typically Gas-fired. But in some dryer lines Oil heated (Thermic oil) dryers offer a lower cost energy source, and provide a finer degree of temperature control.

The most important benefits of Valmet Advantage Yankee dryers come down to two words: proven and choice. Matched exactly to your needs, rest assured you have top safety, availability, long service life and excellent performance along with simple design, quality materials and high-precision machining and welding.

Mottle is an irregularly patterned defect seen as an optical density variation (color variation) with the naked eye with size scale of 0.5 to 5 cm, sometimes oriented. Mottle is a function of the following parameters: Property variations of base paper (porosity, density, thickness, surface or base structure, etc.).

In paper mills, the drying operation is monitored very closely due to its enormous impact on the quality of the final product. ... M.H. Gilkey, Corrosion fatigue and subsequent rupture of a Yankee dryer roll on a modified paper machine, in Hand Book of Case Histories in Failure Analysis, vol 1, ASM International, 2002, pp. 132-135. ISBN: 0 ...

The Yankee dryer is a large heated, fast rotating heated drum used to produce tissue paper. The paper is dried and creped to achieve the desired finished product. Accurate temperature monitoring of the drum surface over its entire width allows for uniform temperature control. Typically, the paper goes from about 45% dryness to 90% dryness at ...

Visit https://goo.gl/XALViG to view the full video and purchase access to our other Tissue courses.The Yankee dryer is a large, steam-heated, pressure vessel...

Walmsleys Ltd are a UK Engineering company specialising in the design, supply and maintenance of paper making machinery, Yankee Dryer services, subsea umbilical manufacturing machines and offshore hardware.

Since the 1980's, the paper has been publicly acknowledging his failures. Ukrainian-American and other organizations have repeatedly called on the Pulitzer Prize Board to cancel Duranty's prize and The Times to return it, mainly on the ground of his later failure to report the famine.

Let's see what new products are now available in USSR from the West!

Industry: Cut and Sew Apparel Manufacturing , Residential Building Construction , Nonresidential Building Construction , Building Equipment Contractors , Building Finishing Contractors See All Industries, Men's and boy's work clothing, Operative builders, Land preparation construction, Plumbing, heating, air-conditioning, Painting and paper ...

Find detailed information on Pulp, Paper, and Paperboard Mills companies in Odintsovo, Moscow Region, Russian Federation, including financial statements, sales and marketing contacts, top competitors, and firmographic insights. Dun & Bradstreet gathers Pulp, Paper, and Paperboard Mills business information from trusted sources to help you ...